Rivian Mom

Active Wheeler

- Joined

- Oct 20, 2024

- Messages

- 246

- Reaction score

- 26

- Rivian

- R1S

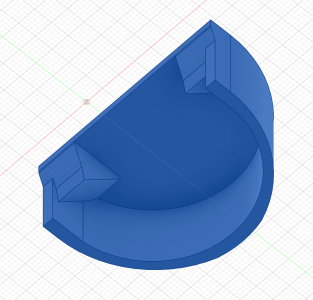

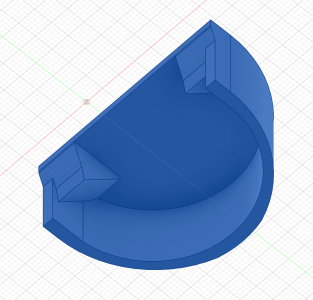

I'm a bit astonished and also very happy with my first ever 3D print. Wanted to design a "shroud" to keep the parts from rotating. Which would allow printing "directional" accessories, or pieces with an extension/offset to the side or forward that would just flop/twist around in whatever direction a force was applied.

This requires fairly specific geometry to "lock-in" around the front and sides, and into the little divots where the metal loop meets the "front" of the cargo tie-down, angles and curves. So I sat down and modeled directly to the scan and printed a single sample.

It fits PERFECTLY, there's not even a fraction of a mm of "give" or twist. It locked in perfectly first try. The tolerances are PERFECT. I'm astonished. It actually works.

Cost of the scanner is entirely justified. This is an absolute game-changer to know "I want to make something that fits into X" or "I want to make something that X can fit into" - and then you scan X, model/design to it, print, and it just works, or at least is so close you can dial it in almost instantly opens the door to making/printing so many more things. Couldn't be happier.

Below is the link that I used to make my print in case anyone is interested. Happy Printing!

store.3dmakerpro.com

store.3dmakerpro.com

This requires fairly specific geometry to "lock-in" around the front and sides, and into the little divots where the metal loop meets the "front" of the cargo tie-down, angles and curves. So I sat down and modeled directly to the scan and printed a single sample.

It fits PERFECTLY, there's not even a fraction of a mm of "give" or twist. It locked in perfectly first try. The tolerances are PERFECT. I'm astonished. It actually works.

Cost of the scanner is entirely justified. This is an absolute game-changer to know "I want to make something that fits into X" or "I want to make something that X can fit into" - and then you scan X, model/design to it, print, and it just works, or at least is so close you can dial it in almost instantly opens the door to making/printing so many more things. Couldn't be happier.

Below is the link that I used to make my print in case anyone is interested. Happy Printing!

Seal 3D Scanner

Seal effortlessly transforms the physical world into 3D models for printing, design, albums, DIY, and reverse engineering.

store.3dmakerpro.com

store.3dmakerpro.com